Astec Pulse Jet Baghouse

Overview

Astec baghouses allow asphalt producers to compete in an age of heightened environmental awareness and increased regulations.

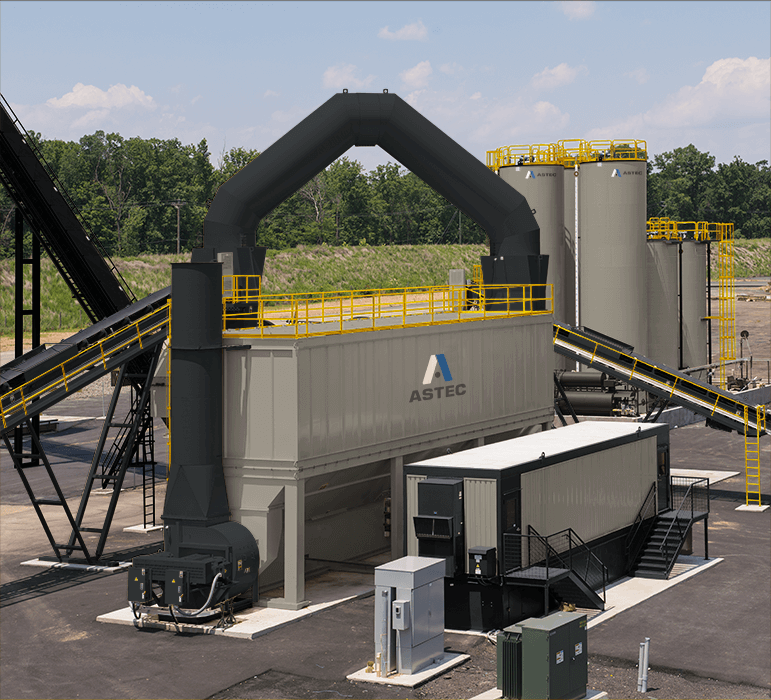

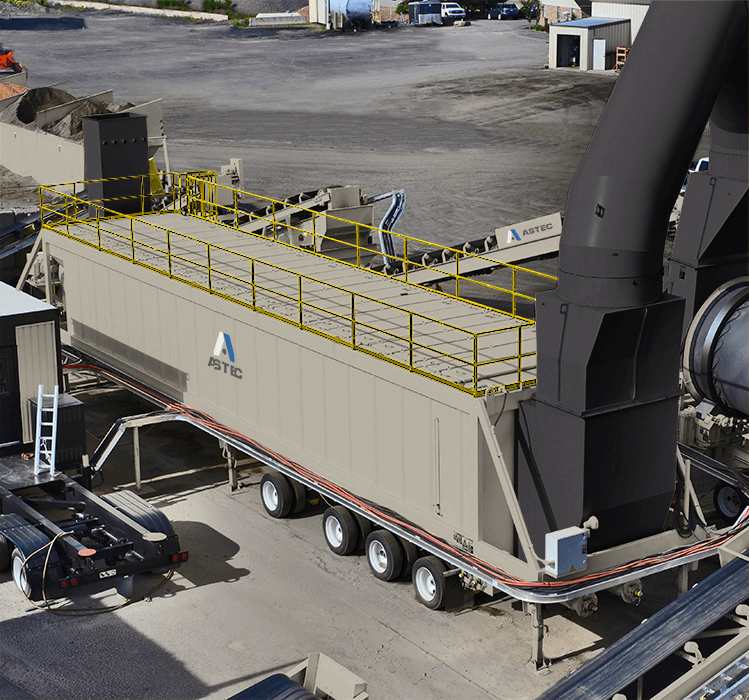

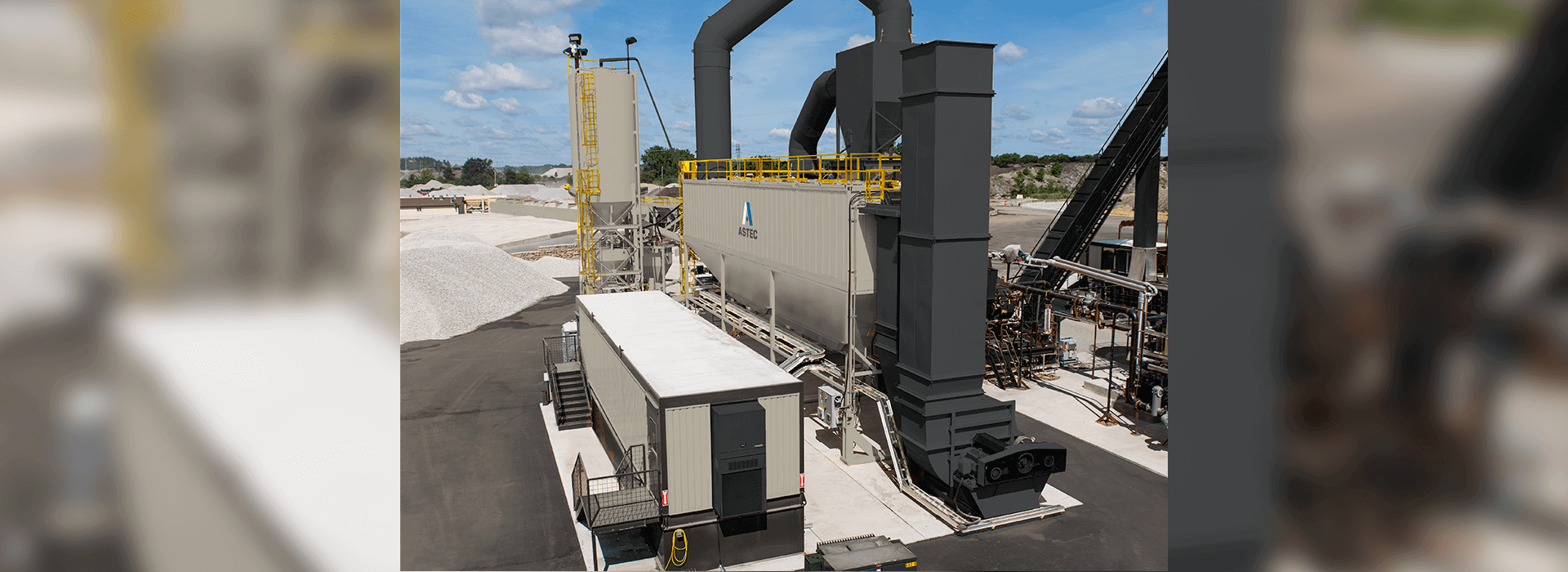

With Astec's pulse jet cleaning system, no bags have to be taken out of service for cleaning. During cleaning mode, blowpipes direct bursts of compressed air into two rows of bags at a time. The shock and momentary back-flow produced by the compressed air pulse causes the bags in the section to expand and expel the collected dust from the surface, allowing it to drop into the hopper.

The relocatable pulse jet baghouse, with primary collector modules, is delivered on steel plate foundations. At the site, the top weldment bolts to the hopper section. Filter bag modules are installed on top, and an airtight seal is created between top and bottom sections. Epoxy coating of the interior stops corrosion. Exhaust fan inlet duct, fan base and stack are pre-assembled and fitted to the baghouse. Constructed with AR-400 abrasion resistant steel at elbows. Pulse valves are mounted internally to promote consistent performance by preventing freeze-up. Capacities start at 34,000 cfm, depending on the plant.

Astec Pulse Jet Baghouse

Applications

-

![]()

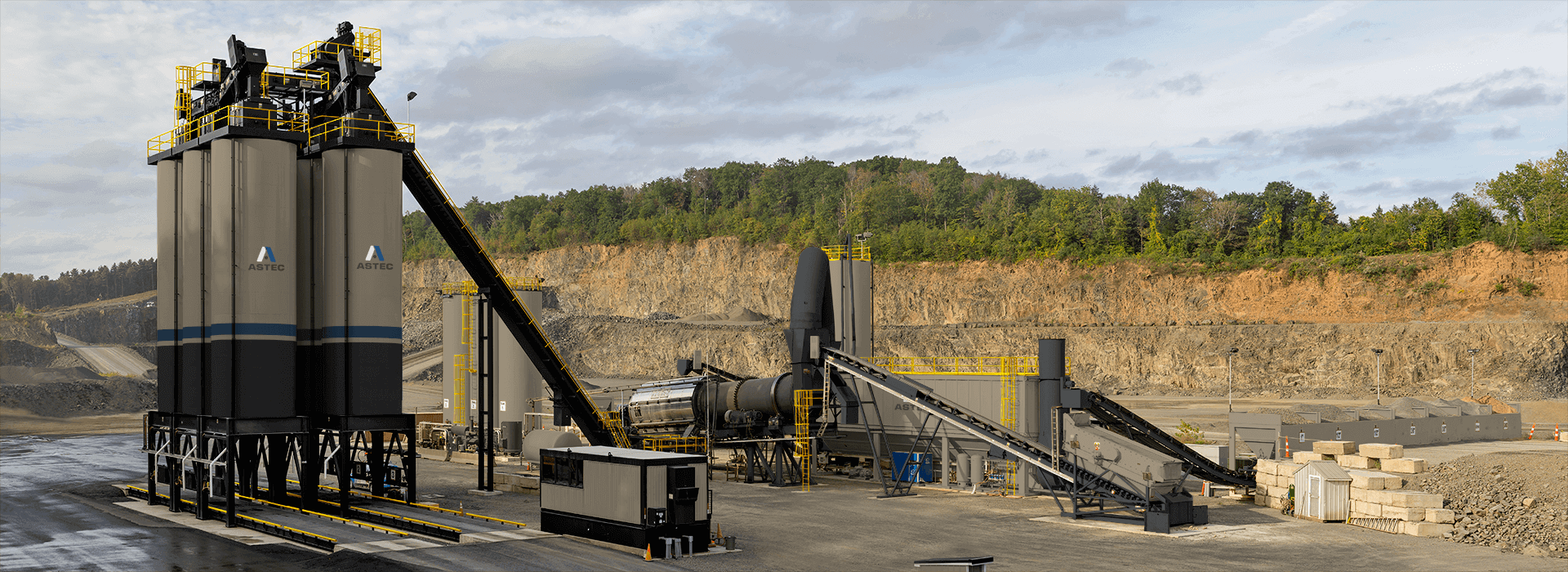

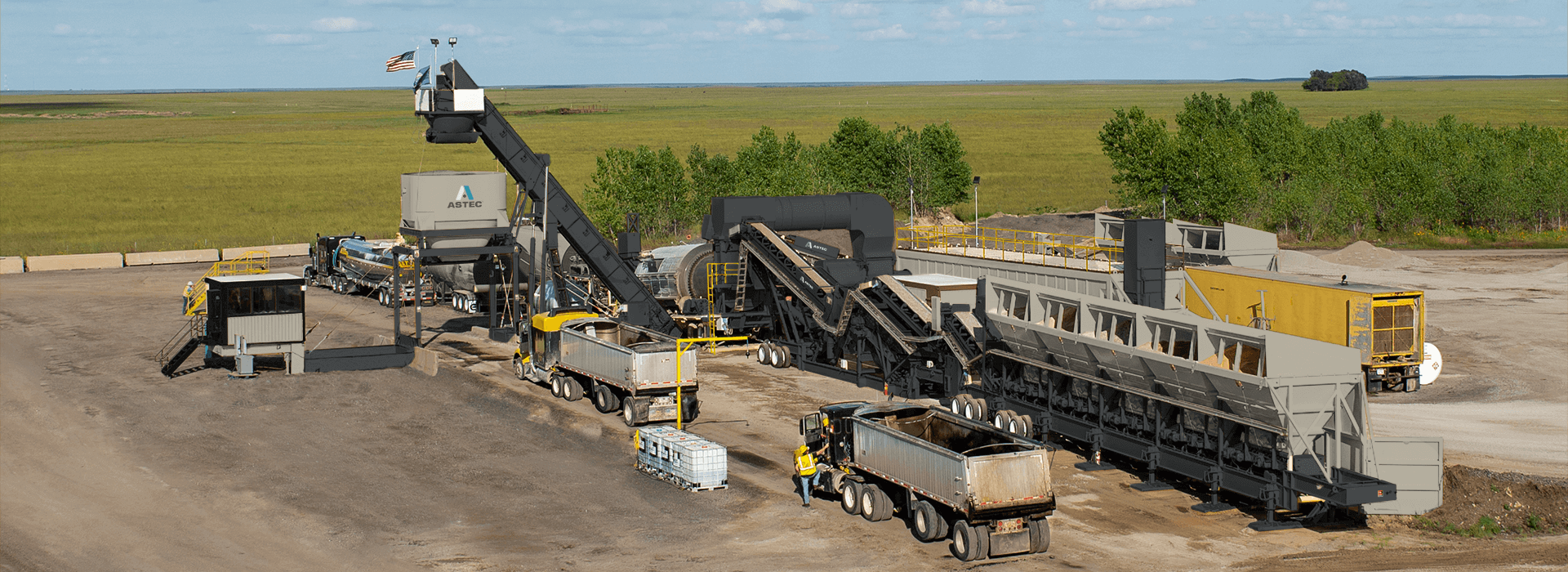

Asphalt Mixing

A thermal mixing process is required to turn aggregates and liquid AC into an asphalt pavement mix for road construction. This makes an asphalt mixing plant necessary for road construction. The complete line of Astec asphalt mixing plants, and its range of capacities and features, gives you the choices and flexibility to create your optimum solution.Learn More